While the forklifts of today are built for efficiency and durability, moving materials hasn’t always been so easy. In this blog, we’ll explore the history of the lift truck design and how it’s changed over the decades to accommodate the evolving needs of worksite operations.

1887: The Platform Lift

During the Industrial Revolution, labor shifted from manual to machine powered and brought significant changes to the manufacturing, transportation and logistics industries. As the economy grew and processes became more mechanized, there was an increasing need for more efficient material handling.

In 1887, the first lift truck was initially used for baggage on the Pennsylvania Railroad. This early lift truck had very little power and was a simple platform just a few inches off the ground. Although this platform lift was not widely adopted, it set the stage for further innovations in forklift technology in the decades to come.

1917: The Tructractor

In 1917, the Clark Material Handling Company introduced the first forklift, known as the Tructractor, which was the first seated counterbalance truck. This machine was designed to improve productivity as it could transport heavy loads with ease. The Tructractor featured a cart in front. Although it was overall functional, it pales in comparison to the power of today’s forklifts.

The Tructractor incorporated an internal combustion engine, which allowed for movement and minimal lifting capacity.

1923: First Modern Forklift

Industries underwent significant growth and expansion in the beginning of the 20th century, particularly in manufacturing and logistics. This led to the invention of the forklift as we know it, by George Raymond Sr.

Designed in 1923, this forklift was groundbreaking because it combined the functionality to move horizontally and lift vertically with a cantilever and tilting masts. Raymond also incorporated a shortened wheelbase and stronger joints for a stable and strong machine.

1942: The Carloader

As manufacturing increased during World War II, there was a growing demand for efficiency, in terms of logistic and warehousing activities. This led to the development of the Carloader forklift in 1942.

The Carloader was a significant advancement in logistics technology because it had an electrical power source and could complete a full, 8-hour shift from one charge. This reduced the operational cost of using fuel and eliminated the downtime associated with stopping to charge the battery. The Carloader forklift played an important role in streamlining logistics and material handling during World War II.

1954: The Reach Truck

As the economic expansion of the post-World War II era continued, there was a growing demand for vertical warehousing solutions. The traditional forklifts of that time were limited in their ability to navigate narrow aisles and reach high stacking levels. So, in 1954, Lansing Bagnall introduced the first narrow aisle electric reach truck, marking a significant development in the field of logistics and material handling.

The introduction of the reach truck provided a narrow and compact design that could maneuver through tight spaces. Its electric-powered operation allowed for clean and efficient use, making it suitable for indoor environments. The reach truck’s most notable feature was its capability to increase the vertical reach, allowing the operator to lift loads up to 50 feet in the air. This innovation greatly enhanced storage capacity and efficiency in warehouses, facilitating the vertical warehousing required by the expanding economic development.

1960s: Safety Measures

Forklift designs evolved to reach new heights and safety became a significant emphasis in the ‘60s. The increasing number of accidents and injuries involving forklifts prompted manufacturers to introduce safety features that would protect both the operators and the loads being transported. One of the most significant additions was backrests, which were added to the masts to help keep loads from falling backward. This safety feature prevented damage to the load and the forklift and ensured the operator’s safety.

Another significant safety feature introduced during this period was a cage placed around the driver to add more protection. This cage guarded the operator against falling material and provided an extra layer of protection in case of an accident. These safety features marked a significant development in the evolution of forklifts, contributing to the overall safety and efficiency of material handling operations.

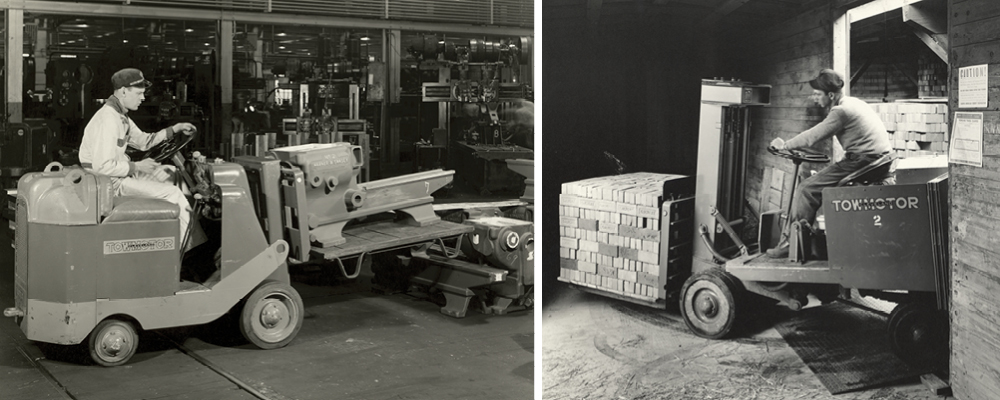

1971: Towmotor to Caterpillar

Shortly after becoming a subsidiary of the Caterpillar Tractor Company in 1965, Towmotor was relocated to Mentor, Ohio and the forklifts were officially rebranded under “Caterpillar” in 1971.

1980s: Ergonomics & Emission Control

During the 1980s, the logistics industry shifted its emphasis towards ergonomic design to prioritize operators’ health and comfort. Manufacturers recognized the importance of reducing operator fatigue, improving productivity and safety, and preventing injuries.

In addition to comfort, regulations were introduced to control emissions from forklifts. Although electric forklifts were available, many gas-powered lift trucks remained in use. Therefore, regulators incorporated emissions control measures such as catalytic converters and diesel particulate filters in new forklift models to reduce exhaust emissions.

1990: Forklift Stabilization

As logistics teams continued to maximize load efficiency, forklift stabilization became a concern in the material handling industry. Load stability mechanisms were introduced to address the issue of vehicles tipping over while carrying heavy loads. One notable advancement during this period was Toyota’s implementation of the System of Active Stability (SAS) and Active Mast Control in 1999. SAS is a technology that automatically levels a forklift’s load, minimizing the risk of tip-overs. Active Mast Control, on the other hand, utilizes advanced sensors to optimize the control of the forklift’s mast to prevent forward and backward tilting. These advancements in forklift stabilization technology represented a significant leap forward in enhancing safety and preventing accidents in material handling operations.

2010: The MCFA-Jungheinrich AG North American Agreement

Junghreinrich AG joined Mitsubishi Caterpillar Forklift America in a distribution and manufacturing agreement to offer advanced electric warehouse products on a larger local level.

Discover the Latest Forklift Designs

Over time, forklifts have evolved to become the indispensable workhorses of jobsites everywhere. When you’re looking for the latest forklift technology, turn to G&W Equipment. Offering a wide range of options, G&W Equipment embraces the latest advancements in electric and gas-powered forklift technology, while also offering driver comfort and safety.

With a wide selection of trusted brands and an expert team to guide you, G&W Equipment ensures you can find the perfect forklift to meet the specific needs of your warehouse. Explore forklifts from G&W Equipment today!