When buying a new forklift, understanding and calculating forklift capacity can help you choose the right model for your business. Knowing forklift capacity allows you to be more efficient with your fleet and improves warehouse safety.

What is forklift capacity?

Forklift capacity is defined as the total weight a forklift can carry safely at a specific load center. Forklifts come with a rated capacity, listed on the data plate.

Rated capacity is a general guideline or recommended limit. It does not take into account factors such as rough terrain or the age of the lift truck (which may result in possible diminished capacity).

Another way to define forklift weight capacity is net capacity. Net capacity ratings factors in the terrain and age of the lift truck in addition to forklift attachments, any modifications to the lift truck and the forklift mast type.

Net capacity, not rated capacity, is the real guideline when it comes to calculating safe forklift capacity.

How do you calculate net forklift capacity?

Now that you see the difference between forklift rated capacity and forklift net capacity, how do you determine the load a specific forklift can carry safely? Calculating net forklift capacity can be complex.

It would seem reasonable that larger lift trucks can carry more weight, and to some extent, this is true. However, it’s not as simple as that. And larger lift trucks do carry a greater risk of tip-overs in certain conditions, such as rough terrain.

Calculating forklift capacity is really an equation that must include a variety of factors specific to the forklift, the load and the jobsite.

It is a mathematical formula that involves:

- Rated capacity

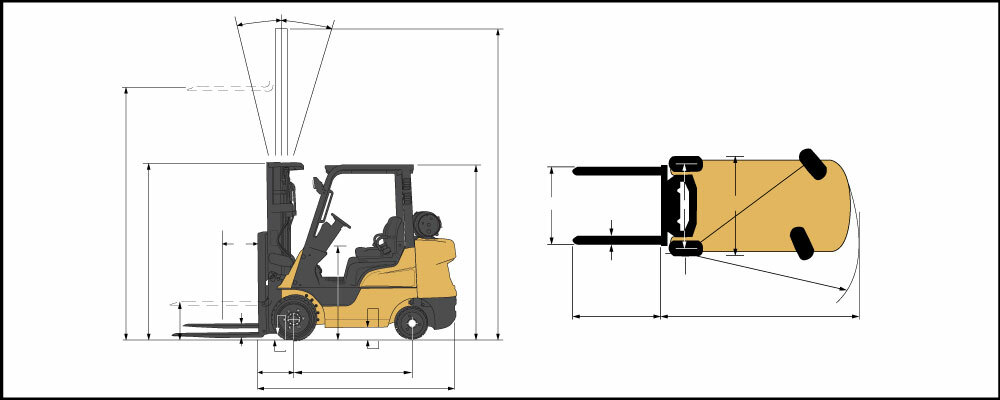

- Distance from various points on the forklift to various points on the load

- The weight of any forklift attachments

Once this is calculated, it is still imperative to add in factors like age of the forklift, the type of terrain and level of wear and tear on the forklift.

Some of the things that will affect the capacity are:

- Load Center: A load that is centered on the forklift tines will be easier to carry than one that is not. The load center is the distance from the front of the forks to the center of gravity of the load. A balanced load with even weight distribution will offer the best carrying capacity.

- Age of the forklift: Over time and with use, your forklift will age and show wear and tear. This can affect forklift capacity.

- Lift height: The higher the lift height, the lesser the load capacity.

- Attachments: Forklift attachments shift the center of gravity and add weight to the forklift.

Why is forklift capacity rating important?

Warehouse safety is dependent upon using forklifts correctly and avoiding forklift accidents. Understanding forklift capacity can help reduce the chance of tip-overs. Carrying a weight that exceeds a forklift’s net capacity, particularly on unstable terrain, can result in a dangerous tip-over.

Trying to carry a load that is too heavy for a particular forklift also can cause steering issues or damage to products if they slide off the forklift tines.

OSHA has regulations related to forklift capacity. Not following these regulations can result in fines and possible legal ramifications for your company.

Help keep your employees safe, as well as protect your warehouse products and forklift fleet, by understanding and following forklift capacity ratings. Make sure your operators have the right forklift training. G&W offers forklift safety training, including customized onsite operator training and “train the trainer” training, so your safety managers can effectively train your operators

Who is capable of calculating forklift capacity?

Experienced forklift operators may have the ability to correctly calculate forklift capacity. The team at G&W also can help you calculate your forklift load capacity. We have a solid knowledge base about various forklift capacity ratings and understand the complexity of calculating net capacity.

We sell a variety of new forklift types including counterbalanced forklifts, electric forklifts, narrow-aisle forklifts, walkie jacks and stackers and more from brands you trust.

Increase Warehouse Efficiency with Forklifts from G&W

If you’re looking for a new forklift or it’s time to update your fleet, talk to us. We can help you find the right forklift for the job.

Contact the forklift experts at G&W today.